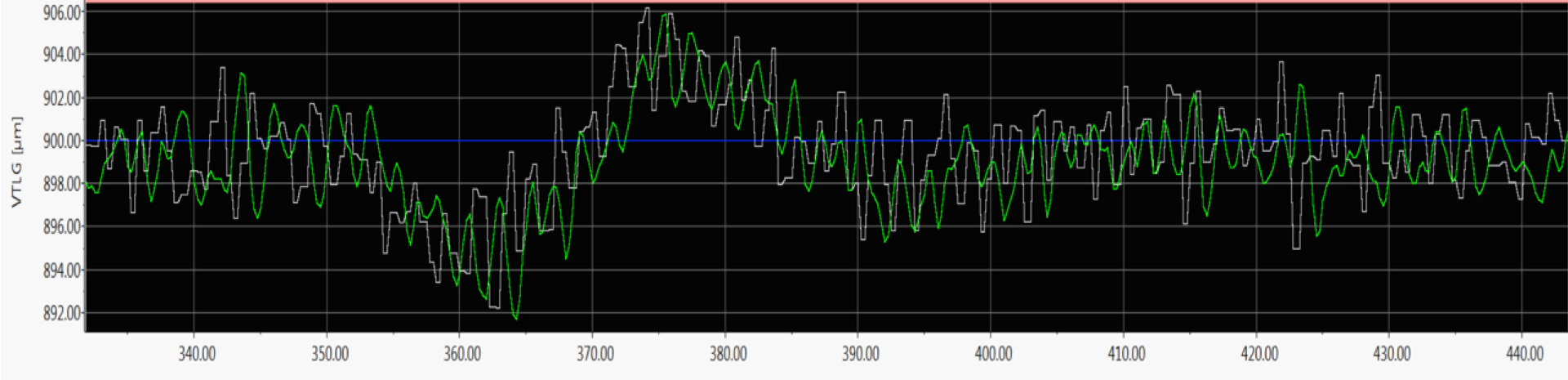

The measuring of the the thickness of metal strips in cold-rolling mills requires an accuracy of ±1 µm.

Until now this has not been practice-oriented possible by laser measurement technology due to the rough conditions in a rolling mill. Today VOLAS sensors are used for this application, and they have proved.

The laser measurement technology with VOLAS sensors will increasingly gain market shares due to the contact-free and alloy-independent measurement.

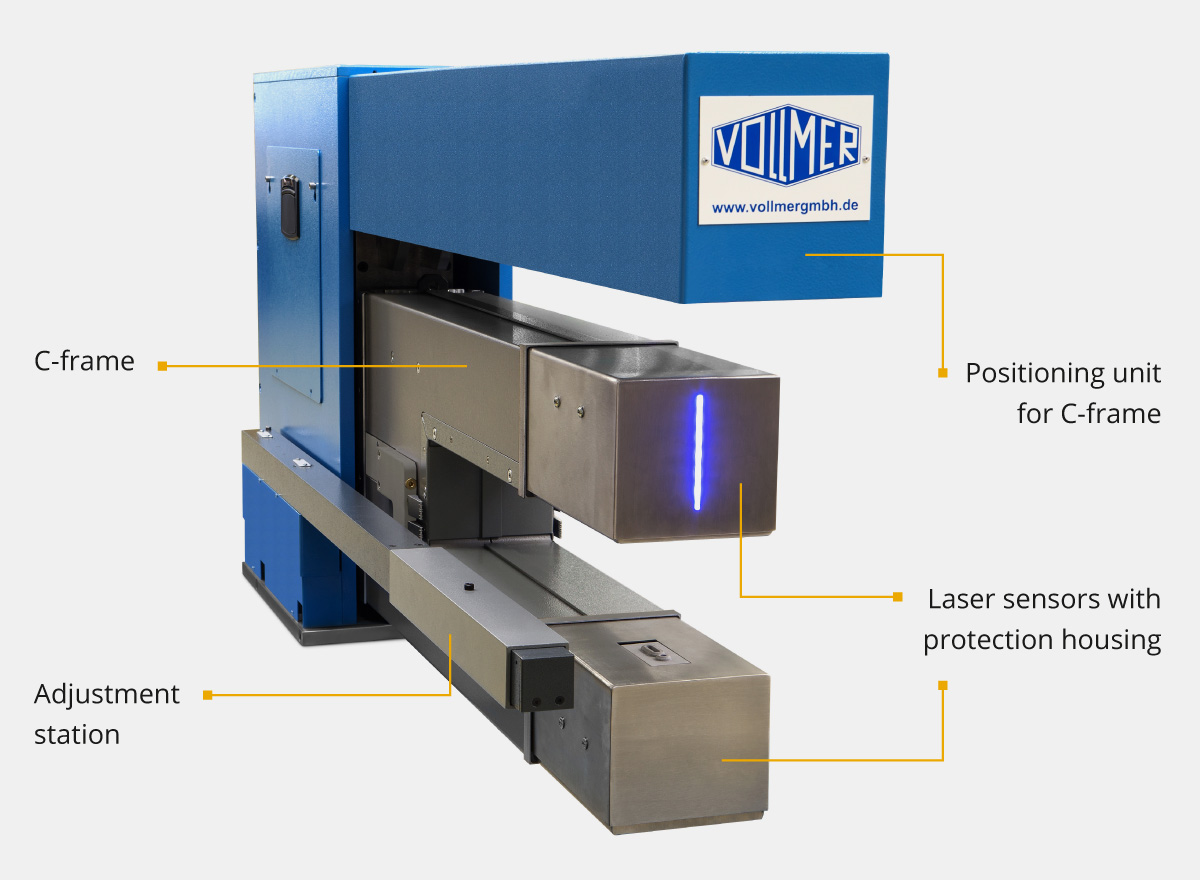

Laser Gauge VTLG

Laser Gauge VTLG